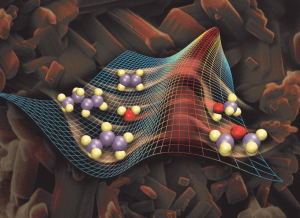

Molecular sieves are crystalline metal aluminosilicates with uniform pores that selectively adsorb molecules based on their size and shape. These materials find wide applications in various industries due to their ability to separate different molecules and remove impurities from liquids and gases.

One of the key features of molecular sieves is their high adsorption capacity, which allows them to effectively remove water, carbon dioxide, sulfur compounds, and other contaminants from natural gas, petrochemicals, and air streams. This makes them essential in processes such as gas drying, dehydration of solvents, and purification of hydrocarbons.

In addition to their adsorption properties, molecular sieves are also used as catalysts in various chemical reactions. By providing a large surface area and specific pore sizes, they can facilitate reactions such as isomerization, dehydration, and cracking in the petrochemical and refining industries.

Overall, the unique properties of molecular sieves make them indispensable in modern industrial processes where precise separation and purification of molecules are required to meet stringent quality and environmental standards.